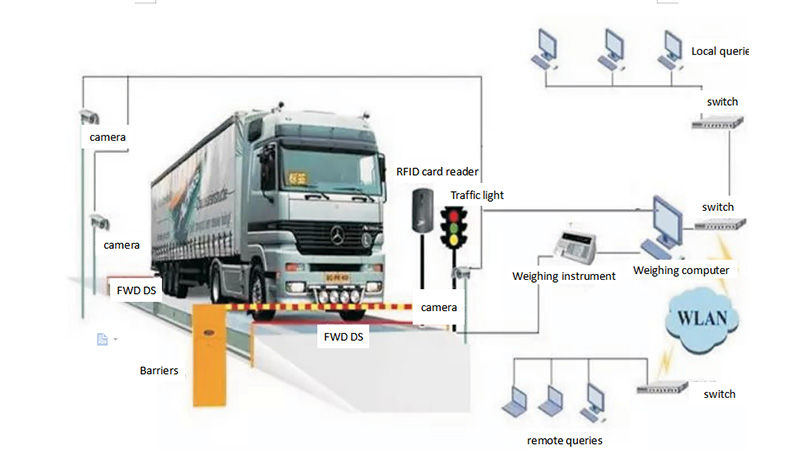

RFID intelligent weighting system consists of electronic truck scale, computer, printer, video surveillance, RFID card-reading system, traffic light , barrier and anti- remote cheat device. On the basis of existed electronic truck scale, the upgrade can be realized by added software and hardware into system. The system adopts standard WINDOWS interface, chinese language and simple operation make it convenient and easy to view and report, meaning that measuring can be conducted at any time, and the more accurate and reliable weighting data can improve work and economy efficiency. The system consists of two user-friendly operating patterns: manual operation and intelligent unmanned operation.

contact

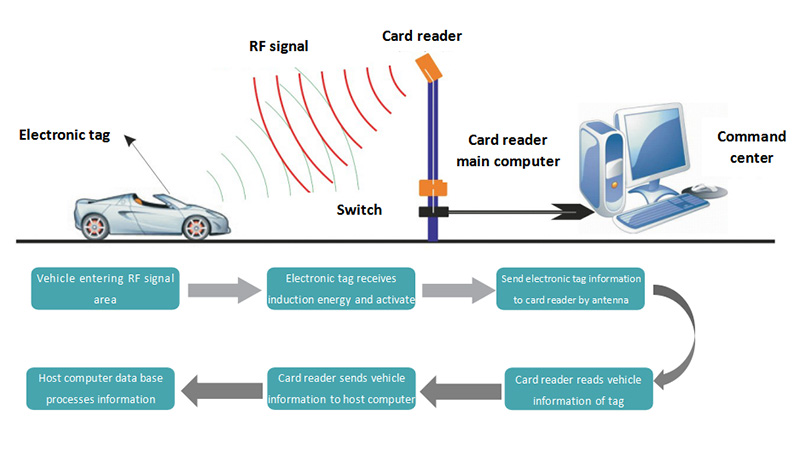

Fast reading rate

instantaneous data reading

Small size

diverse shapes

Penetrability and no barrier read

RFID is able to penetrate paper, wood, plastic and other non-metal or non-transparent material when they are covered.

Large data memory capacity.

High safety

since RFID carries electronic information, its data information can be protected by password and not easy to be forged or altered.

Through automatic plate number identification and accurate measuring, RFID intelligent weighting system can prevent company from economic loss because of outsider’s cheating. In addition, labor intensity and failure rate caused by human weighting will be greatly reduced when intelligent weighting system applied; the traditional manual operation model will be upgraded into manual management model, so as to improve the transparency of management process and informationization of company.

copyright Hunan Qianmeng Industrial Intelligent System address:28 Kangwang Industrial Park, Yueyang record number:湘ICP备20000218号-1business license

Technical Support:Competition network