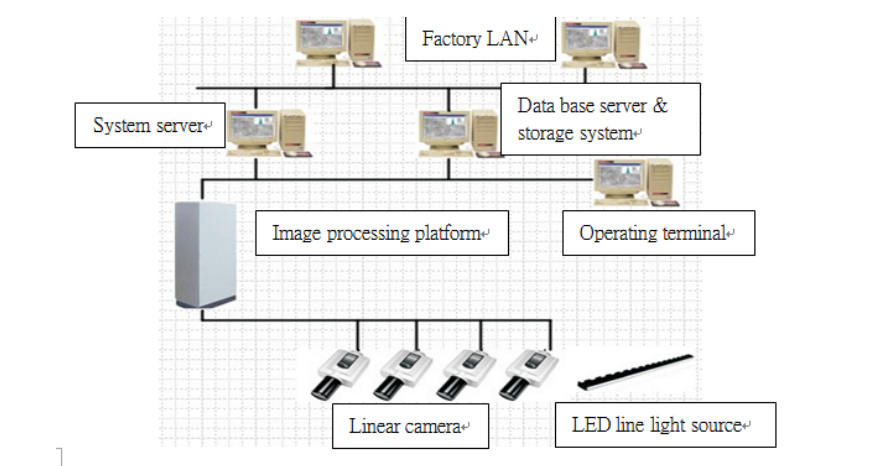

Surface quality online inspection system detects defect on finished/semi-finished products through machine vision technology, scans surface line by line through industrial linear camera so as to form image of finished/semi-finished products surface, then collects information of location, type and size about defect through algorithm analysis, which is convenient for clients to analyze the cause of flaw, eliminate flaws and improve quality. Object of system includes: steel: cold-rolled sheet, hot-rolled sheet, galvanized sheet, stainless steel plate; tinsel: aluminum foil, copper foil; copper strips, copper foil sheet, aluminum sheet, copper sheet, aluminum strips; metal composite products: precious metal composite products, thermometal composite products, etc.

contact

Non-contact real-time detection of material surface defects

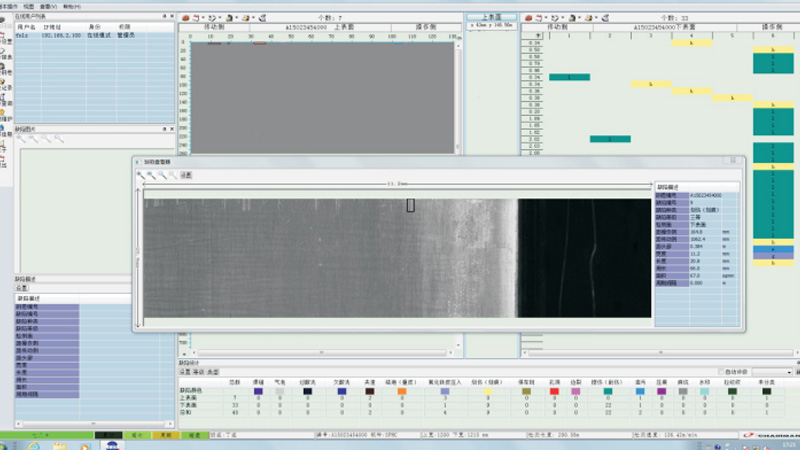

Automatic real-time display of major defect images

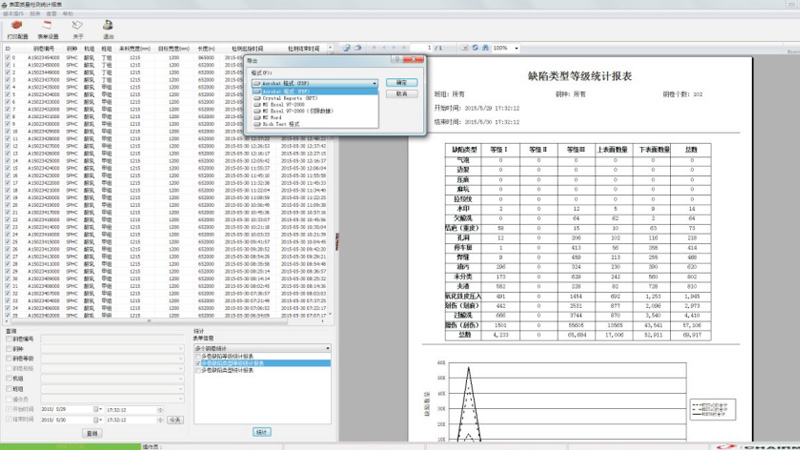

auto reporting as user requested, able to print report and defect images.

AI self-learning defect classifier, able to improve defect base, upgrade easily, and lift recognition rate

set alarm conditions according to defect type and severity level, able to set defect severity level rule

measurement data can be exported to other storage medium, support offline viewing

the earliest periodic defect finder, able to calculate periodic interval distance

able to calculate the width of finished/semi-finished products

able to save original image of upper and lower surfaces of the whole finished/semi-finished products, no need open to verify

Steel-making logistics tracking and intelligent scheduling management system consists of: scrap management, molten steel pre-treatment management, converter production management, refining production management, continuous casting production management, steel ladle management and warehouse management subsystem.

Steel-making logistics tracking and intelligent scheduling management system consists of: scrap management, molten steel pre-treatment management, converter production management, refining production management, continuous casting production management, steel ladle management and warehouse management subsystem.

copyright Hunan Qianmeng Industrial Intelligent System address:28 Kangwang Industrial Park, Yueyang record number:湘ICP备20000218号-1business license

Technical Support:Competition network